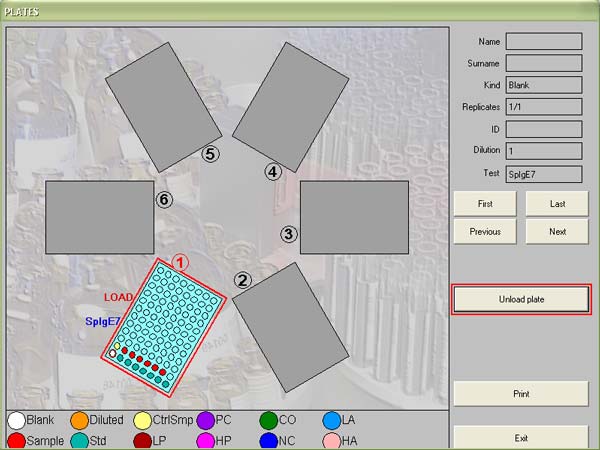

- Capacity of 6 microtiter plates (ELISA)

- Walk-Away-System

- Ideal for various ELISA applications of laboratory diagnostics:

Determination of hormones, tumor markers, infectious diseases … - Up to 12 different assays at same time

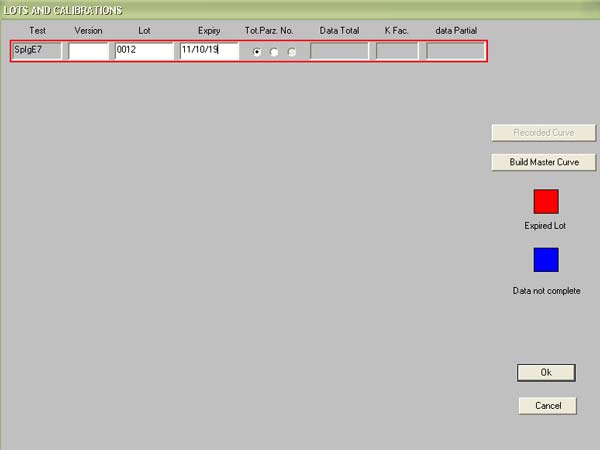

- Standard curve recall and recalibration

- Time management system

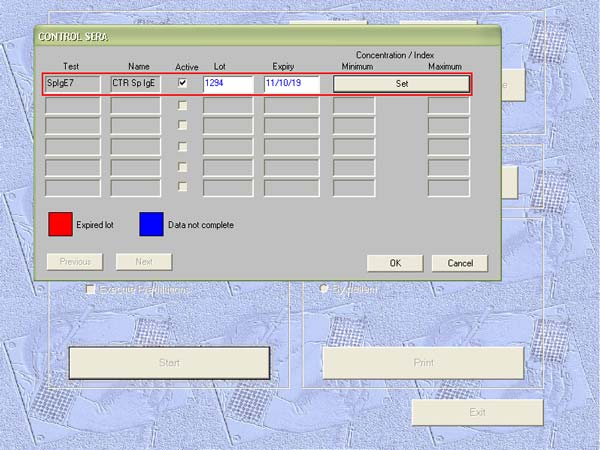

- Quality control functions

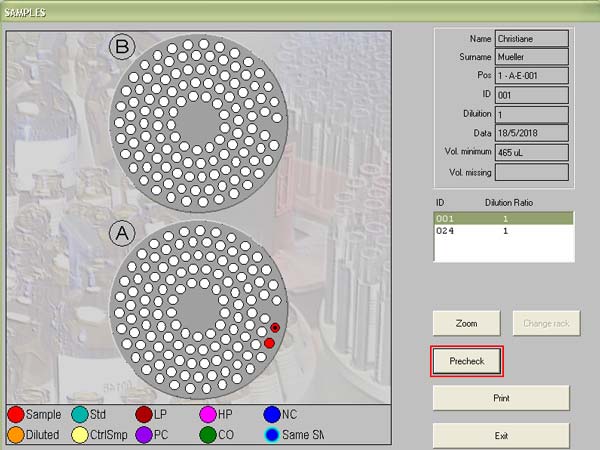

- Monitoring the entire test run

- No disposable tips

- Flexible user interface

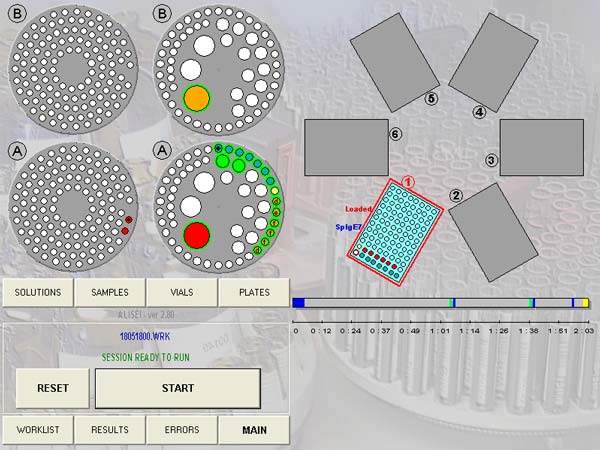

Fully automatic microtiter plates ELISA Analyzer

Solution for processing ELISA kits

Simple ‘loading’ with reagent and sample racks, which can be stored in the refrigerator.

6 microtiter plates (ELISA) are incubated, shaken and washed independently of each other

Reagents and samples

- Removable rotating racks for reagents and sample tubes

- Maximum capacity: 240 sample tubes

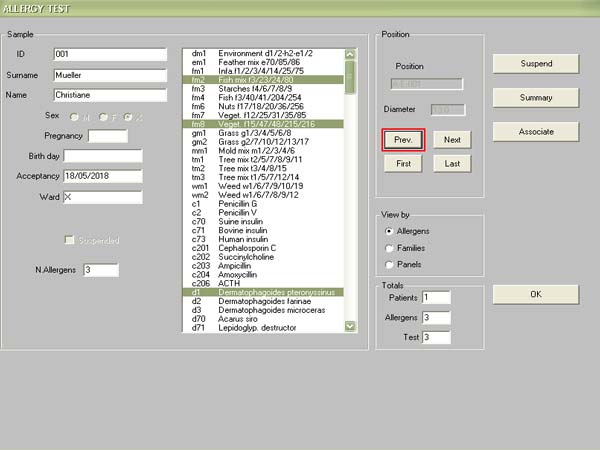

- Simultaneous loading of up to 12 reagent sets (or up to 81 allergens)

Multiple reagents on two separate racks can be loaded on the machine. The charging area is easily accessible for easy loading of reagents, samples and polymer tips through a transparent, large sliding window. The reagent and sample racks are easily removable with practical handles to quickly store the reagents in the refrigerator.

Double pipetting system

two independent needles

Barcode reader offers reliability

Barcode reader reads samples and reagents

Dosing and diluting

Pipettier speed serum: 700 samples/hour

Pipettier speed reagents: 1500 Wells/Hour

Liquid level detection for optimal detection of fibrin clots and insufficient volume

Incubate and mixing

The microtiter plate carousel can perform linear shaking with a programmable intensity and period for each plate separately.

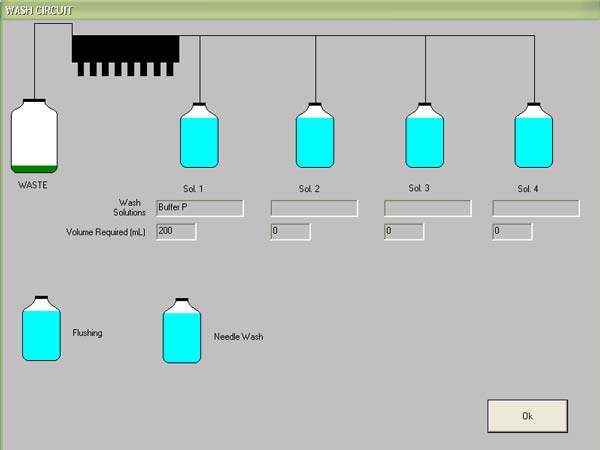

8-channel washing station

Number of cycles: programmable from 1 to 9 cycles

Impact time: programmable from 1 second to 3 minutes

Pressure: programmable

Each protocol can be programmed by the operator with multiple washes that differ in cycle, volume, holding time, and pressure.

Alisei Q.S.: 8-channel washing station

Reading

The normally provided filters: 405, 450, 492, 550 and 620 nm

Reader range: 0-3 OD in Bichromatism; 0-9 OD in polychromatism

Alisei Q.S.: 8-channel photometer

Equipment maintenance

Preparation and follow-up of working time: 5 minutes per day

No warm-up phase required.

Self-diagnostic and alarm procedures are an essential part of the Alisei Q.S..

daily

Cleaning at the end of the run – fully automatic.

weekly

General cleaning of the workspace of liquids.

Empty all tanks to remove residual buffers. Rinse with DI water.

Empty all tanks to remove residual buffers. Rinse with DI water.

monthly

Wipe off the work area, plate trays, and waste bin.

Check tanks and visible hoses

Check tanks and visible hoses

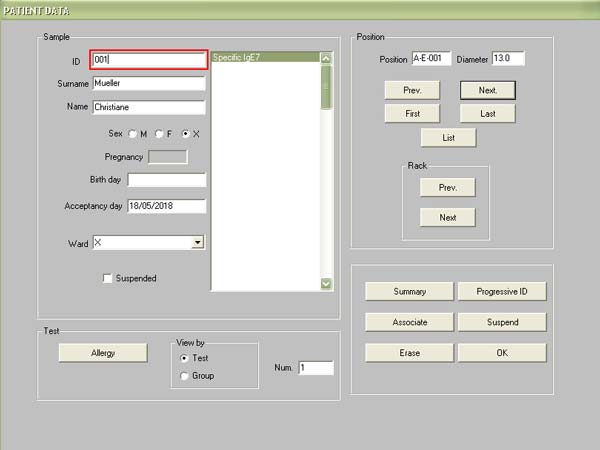

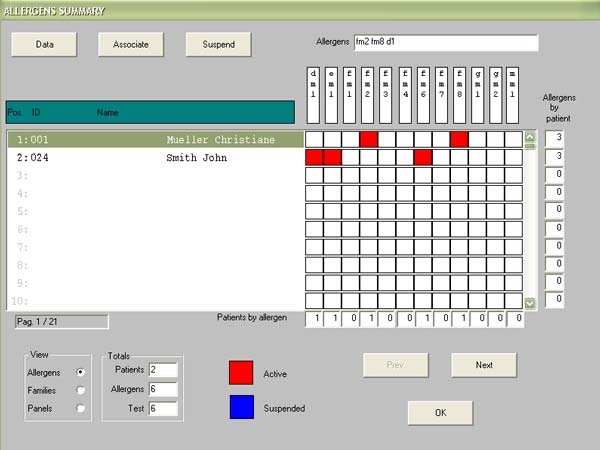

Smart software

- Programming and changing test protocols

- Insert work lists with all relevant patient data

- Monitoring the entire test run

- View and manage the final results

- Personalizing and printing the patient report

- Standard curve retrieval function

- T. M. S. (Time Management System)

- Quality control functions

- Compatible with laboratory information systems

ELISA results manager

Logistic curve-based parametric methods such as 4-parameter logistics (4PL) and Live Parameter Logistic (5PL) models have the closest correlation with real signal concentration dependence in ELISA assays.

The calculated results based on these methods have very little variability and high reproducibility. Therefore, they are considered the most suitable models for both competitive and “sandwich” ELISAs viewed. However, these calculation modes are not always available in the standard equipment software for demonstrating the ELISA test results. In this case, the ELISA Results Manager software provides an upgrade of the results analysis.

Key program benefits:

- Calculating results based on 4PL and 5PL models

- Visualization of the calibration curves

- Simplified information entry

- Processing the data received on an ELISA device

- Calculation of sample concentrations and statistics

- Printable results

Technical specifications Alisei Q.S.

Dosing

microtiter plates:

6

Parameter:

max. 12 in one run

Samples:

max. 360 in one run

Pipetting volume:

7 µL – 1000 µL

Precision tip 10 µL:

less than 2.5%

Tipp 100 µL:

less than 1%

Needle:

less than 1.5%

Throughput samples:

700 / h (500 µL washing)

Throughput reagents:

1400 Wells / h

Fill level sensor:

Capazitive for needle

Incubators:

6

Temperature:

RT / RT +5 °C bis +45 °C

Heating time:

5 min

Washing

Buffer:

4 with filler stander recognition

Stations:

1

Liquid trap:

10L with “Full” sensor

Photometer

Units:

1

Reading:

from 0-3 OD (mono / dual / triple wavelength)

Spectral range:

400 – 700 nm

Interference filters:

5

Software

Operating system:

Windows 10

Interface:

Bidirectional ASTM (LIS compatible)

Internal quality control:

Levey Jennings and Westguard rules

Data reduction:

Standard interpolations

Dimensions

Depth:

73 cm

Height:

60 cm

Width:

140 cm

Weight:

100 kg

Electrical specifications

Voltage:

110 or 220 V AC

Frequency:

50-60 Hz

Power:

800 VA